carbon nanotubes

Latest

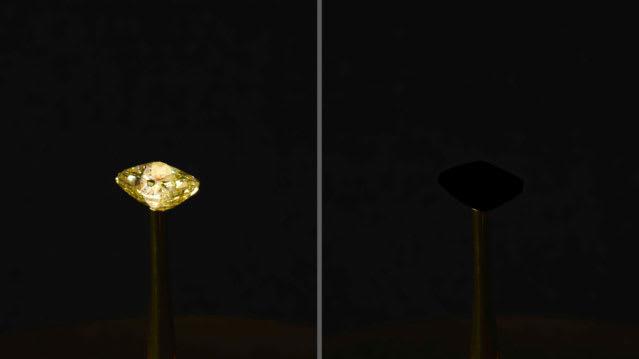

MIT scientists accidentally create the blackest material ever

Good news for goths -- black somehow just got even blacker. MIT engineers have cooked up a material that's 10 times blacker than anything else previously reported. Capturing more than 99.995 percent of any incoming light, the material is made of vertically aligned carbon nanotubes (CNTs) grown on chlorine-etched aluminium foil. And it was discovered by accident.

Rachel England09.13.2019

Inhabitat's Week in Green: superdogs and a cave museum

Each week our friends at Inhabitat recap the week's most interesting green developments and clean tech news for us -- it's the Week in Green. So far Elon Musk has created next-gen spacecraft and some of the world's best electric cars -- could a futuristic airplane be next? This past week, Musk announced that he'd like to build a "pretty cool supersonic, vertical takeoff and landing electric jet." In other transportation news, automakers had a Back to the Future field day last week. Stanford rolled out a self-driving DeLorean; Toyota showcased a special Mirai with gull-wing doors and a flux capacitor; and students built an all-electric version of Doc Brown's time-traveling car. A sleek solar-powered car won the World Solar Challenge by rocketing across the Australian Outback in four days. And we took a test-drive of the all-new, completely rebuilt 2016 Chevrolet Volt, which just hit the market in California.

Inhabitat10.25.2015

Moore's Law in action: making our machines ever more micro

Over the past few decades, engineers have leveraged Moore's Law to the fullest, resulting in powerful ultrathin laptops and feature-rich miniature wearables. Back in 1981, a 23-pound Osborne 1 computer was considered portable, with 64KB of onboard memory. Today, smartphones weigh just a few ounces and easily pack 128GB of storage. There's also a vastly more complex architecture of circuits and sensors inside these devices, all at a scale nearly invisible to the eye. It's taken us decades to develop and shrink down these microelectronics to where they are today, which is no small feat. Join us as we ride the ever-shrinking gadget wave from its early days to some of the nanoscopic creations at work today.

Jon Turi06.13.2015

Stanford researchers create 'world's first' all-carbon solar cell, do it on the cheap

Harnessing the awesome power of the Sun isn't just dependent on the efficiency of solar cells, but also on making them affordable. Current techniques aren't exactly cheap, but researchers from Stanford University think they've made a bit of a breakthrough by producing a relatively inexpensive photovoltaic cell using nothing but carbon. We're sure other scientists might disagree with the 'world's first' claim, but those at Stanford think it's a matter of language, and that these other pretenders are "referring to just the active layer in the middle, not the electrodes." The team selected a trio of carbon types to use in their cell: a mixture of nanotubes and buckyballs make up the light-absorbing layer, while graphene is being utilized for the electrodes. The carbon amalgam can be applied from solution using simple methods, meaning the flexible cells could be used to coat surfaces, although you won't be seeing it smeared over anything too soon. The prototype only touts a "laboratory efficiency of less than 1 percent," so it can't compete with traditional solar cells just yet. Also, it only absorbs a sliver of the light spectrum, but the researchers are looking to other forms of the wonder element which could increase that range. They are hoping that improving the structure of the cells will help to boost their efficiency, too. They might never generate the most energy, but the all-carbon cells can remain stable under extreme conditions, meaning they could find their calling in harsh environments where brawn is a little more important than status, or looks.

Jamie Rigg11.01.2012

IBM Labs develops 'initial step' towards commercial fabrication of carbon nanotubes

Commercialization of carbon nanotubes is one of the holy grails of next-gen computing, and IBM thinks it's made crucial steps toward making this a reality. This isn't the first time that we've heard such a claim, of course, but IBM's considerable resources will make this particularly interesting. The specific problem it's been tackling is placing enough semiconducting nanotubes together to be useful in commercial chips, with current attempts being more in the hundreds, rather than billions that would be required. The new approach uses ion-exchange chemistry that allows controlled placement of nanotubes at two orders of magnitude greater than before, with a density of roughly a billion per square centimeter. To achieve this, the nanotubes are mixed with a soap-like substance that makes them water-soluble. Next, a substrate comprising two oxides and a hafnium oxide "trench" is immersed in the soap-solution, which results in the nanotubes attaching to the hafnium oxide canals with a chemical bond. Simple when you think about it! IBM hopes that as the materials and method are readily accessible now, that industry players will be able to experiment with nanotube technology at a much greater scale. Though, as we've become accustomed, there's no solid timescales on when this might realistically unfold.

James Trew10.28.2012

MIT pencils in carbon nanotube gas sensor that's cheaper, less hazardous (video)

Carbon nanotube-based sensors are good at sniffing out all kinds of things, but applying the cylindrical molecules to a substrate has traditionally been a dangerous and unreliable process. Now, researchers at MIT have found a way to avoid the hazardous solvents that are currently used, by compressing commercially available nanotube powders into a pencil lead-shaped material. That allowed them to sketch the material directly onto paper imprinted with gold electrodes (as shown above), then measure the current flowing through the resisting carbon nanotubes -- allowing detection of any gases that stick to the material. It works even if the marks aren't uniform, according to the team, and the tech would open up new avenues to cheaper sensors that would be particularly adroit at detecting rotten fruit or natural gas leaks. For more info, sniff out the video after the break.

Steve Dent10.10.2012

Ubiquitous nanotubes could reboot Edison-era nickel-iron battery technology

Back in the 1920s, Thomas Edison's dream of an electric automobile was ultimately foiled by those meddling petroleum engines. But thanks to nanotube research from Stanford University, one legacy from that era may regain some glory: nickel-iron batteries. It turns out that carbon nanotubes doped with nickel and iron crystals can top up the normally slow-charging cells in a matter of minutes -- according to the scientists, that's almost 1,000 times faster than in the past. Although the batteries couldn't power your Volt or Prius due to a lack of energy density, they could give an extra jolt to their lithium-ion siblings for quicker starts and regenerative braking. The researchers are working on improving stability to allow more charging cycles, but it might be an extra in-your-face for Edison if it pans out.

Steve Dent06.28.2012

All-carbon solar cell draws power from near-infrared light, our energy future is literally that much brighter

What's this orange-like patch, you ask? It's a layer of carbon nanotubes on silicon, and it might just be instrumental to getting a lot more power out of solar cells than we're used to. Current solar power largely ignores near-infrared light and wastes about 40 percent of the potential energy it could harness. A mix of carbon nanotubes and buckyballs developed by MIT, however, can catch that near-infrared light without degrading like earlier composites. The all-carbon formula doesn't need to be thickly spread to do its work, and it simply lets visible light through -- it could layer on top of a traditional solar cell to catch many more of the sun's rays. Most of the challenge, as we often see for solar cells, is just a matter of improving the energy conversion rate. Provided the researchers can keep refining the project, we could be looking at a big leap in solar power efficiency with very little extra footprint, something we'd very much like to see on the roof of a hybrid sedan.

Jon Fingas06.22.2012

Nanotubes sniff out rotting fruit, your dorm room might be next

Our favorite ultra-skinny molecules have performed a lot of useful functions over the years, but keeping fruit flies away was never one of them. Now MIT scientists, with US Army funding, have discovered a way to give these nanotubes the canine-like sense of smell needed to stop produce spoilage and waste. Doping sheets of them with copper and polystyrene introduces a speed-trap for electrons, slowing them and allowing the detection of ethylene gas vented during ripening. A sensor produced from such a substance could be combined with an RFID chip, giving grocers a cheaper way to monitor freshness and discount produce before it's too late. If that works, the team may target mold and bacteria detection next, giving you scientific proof that your roommate needs to wash his socks.

Steve Dent05.01.2012

Sensitive scales can weigh individual atoms, ensure perfect recipes

Those of you who have navigated beyond using an Easy-Bake Oven will know that weighing out ingredients is a chore. Then again, it's nothing compared to the sort of balancing that takes place at the Catalan Institute of Nanotechnology, where a team has developed a method of weighing individual protons. Using heated, shortened carbon nanotubes in a vacuum, the scale vibrates at different frequencies depending on what molecules are balanced on top. The Yoctogram-scale will enable scientists to diagnose health conditions by finding differences in mass, identifying elements in chemical samples that only differ at the atomic level and ensuring you never over-flour your batter mix again.

Daniel Cooper04.02.2012

GE turns butterfly-inspired tech into cheap, accurate thermal sensors (video)

When last we heard from GE and its Morpho-butterfly inspired sensors, all the talk was about detecting chemicals. And, with $6.3 million in funding coming from DARPA, we're not surprised. In the latest issue of Nature Photonics, however, the company's researchers show that the wing-like structures are just as good at detecting heat as they are ricin attacks. By coating them with carbon nanotubes the team was able to create a sensor sensitive to temperature changes as small as 0.02 degrees Celsius with a response rate of 1/40 of a second. The sensors could eventually find their way into imaging devices and medical equipment, and are expected to cost just a fraction of similar technologies currently on the market. Of course, since DARPA is still involved with the project, there are some potential security uses as well -- such as screening devices and fire detection. Head after the break for a video and some PR.

Terrence O'Brien02.15.2012

Nanotech-enhanced 'smart paint' promises to detect structural damage

We've seen scientists explore a number of ways to make paint "smarter" over the years, and now a team of researchers at the University of Strathclyde in Glasgow have devised a method that they say could do nothing short of "revolutionize structural safety." The key to that is some novel nanotechnology that effectively turns the paint into a sensor network that's able to detect minor structural faults before they become a severe problem. More specifically, the paint consists of a mix of highly aligned carbon nanotubes and a recycled waste material known as fly ash -- when the nanotubes bend, the conductivity changes, indicating that there could be a structural problem developing. What's more, the fly ash is also said to give the paint a cement-like structure, which the researchers say could let it be used in harsh conditions where traditional structural monitoring can prove difficult (and expensive).

Donald Melanson01.30.2012

IBM builds 9 nanometer carbon nanotube transistor, puts silicon on notice

It's not the smallest transistor out there, but the boffins at IBM have constructed the tiniest carbon nanotube transistor to date. It's nine nanometers in size, making it one nanometer smaller than the presumed physical limit of silicon transistors. Plus, it consumes less power and is able to carry more current than present-day technology. The researchers accomplished the trick by laying a nanotube on a thin layer of insulation, and using a two-step process -- involving some sort of black magic, no doubt -- to add the electrical gates inside. The catch? (There's always a catch) Manufacturing pure batches of semiconducting nanotubes is difficult, as is aligning them in such a way that the transistors can function. So, it'll be some time before the technology can compete with Intel's 3D silicon, but at least we're one step closer to carbon-based computing.

Michael Gorman01.28.2012

Cheap electronic skin edges us closer to cyberpunk future

Researchers working for the Department of Energy's Berkeley Lab have figured out how to create relatively inexpensive "electronic skin" comprising carbon nanotubes enriched with semiconductors. Their process involves an enriched single walled carbon nanotube (SWNT) solution embedded in a honeycomb pattern of hexagonal holes to make it more flexible and stretchable - it's so limber, they wrapped it around a baseball, as you can see in the photo above. Combined with inkjet printing of electrical contacts, the technology paves the way for making flexible, wearable computers and a host of other cool things that William Gibson and other cyberpunk authors thought of back in the 1980s: smart bandages, flexible solar cells and electronic skin that can sense touch. Bring on the Zeiss eye implants and neural interface jacks!

Peter Cohen12.15.2011

Researchers use inkjet acumen to create wireless explosive sensor from paper

Meet Krishna Naishadham and Xiaojuan (Judy) Song. They're researchers at the Georgia Institute of Technology, and those little devices they're holding may one day save you from an explosive device. This petite prototype is actually a paper-like wireless sensor that was printed using basic inkjet technology, developed by professor Manos Tentzeris. Its integrated lightweight antenna allows the sensor to link up with communication devices, while its functionalized carbon nanotubes enable it to pick up on even the slightest traces of ammonia -- an ingredient common to most IEDs. According to Tentzeris, the trick to such inkjet printing lies in the development of "inks" that can be deposited at relatively low temperatures. These inks, laced with silver nanoparticles, can then be uniformly distributed across paper-based components using a process called sonication. The result is a low-cost component that can adhere to just about any surface. The wireless sensor, meanwhile, requires comparatively low amounts of power, and could allow users to detect bombs from a safe distance. Naishadham says his team's device is geared toward military officials, humanitarian workers or any other bomb sniffers in hazardous situations, though there's no word yet on when it could enter the market. To find out more, careen past the break for the full PR.

Amar Toor10.31.2011

Stanford builds super-stretchy skin sensor out of carbon nanotubes (video)

An artificial skin that senses pressure, pinches and touch sounds like a macguffin from The Outer Limits (the episode "Valerie 23" if we recall correctly), but that's what a team from Stanford University has cooked up on the back of its pick-up truck. Sensors made of silicon films with a matrix of liquid carbon nanotubes ensure the material snaps back to its original shape no matter how frequently it's pulled about. When compressed, the electrical conductivity of the skin changes, and by measuring where and by how much, it knows the location and pressure of where you jab your fingers. The team wants to combine this super stretchy film with a much more sensitive sensor and if it can do it, then the technology could end up as an artificial skin for burn victims, covering prosthetic limbs or even replacing your multitouch display -- just be careful, you might hurt Siri if you pinch-to-zoom her too hard.

Daniel Cooper10.25.2011

Dipping capacitors and batteries in nanotubes could improve capacity

Stanford researchers figured out that, by dipping electrodes for super capacitors in a solution of carbon nanotubes or a conductive polymer they could increase the charging capacity by up to 45-percent. The team started working with composite electrodes of graphene and manganese oxide, since manganese is cheap and plentiful, but were hamstrung by its low conductivity. The thin coating of more conductive material greatly boosted the capacitance of the electrodes, and thus their ability to hold a charge. Further tests are still required to find the actual energy density of the dipped electrodes, but lead researchers Yi Cui and Zhenan Bao are already working on a way to apply the same technique to batteries.

Terrence O'Brien10.06.2011

Invisibility cloak made of carbon nanotubes uses 'mirage effect' to disappear

If the phrase "I solemnly swear I'm up to no good" means anything to you, you'll be happy to know that scientists have come one step closer to a Potter-style "invisibility cloak" so you can use your Marauder's Map to the fullest. With the help of carbon nanotubes, researchers have been able to make objects seem to magically vanish by using the same principle that causes mirages. As anyone who's been especially parched along Route 66 knows, optical illusions occur when heat changes the air's temperature and density, something that forces light to "bend," making us see all sorts of crazy things. Apply the same theory under water using nanotubes -- one molecule carbon coils with super high heat conductivity -- and scientists can make a sheet of the stuff "disappear." Remember, it only works underwater, so get your gillyweed ready and check out the video after the break.

Lydia Leavitt10.05.2011

Bee venom used to create ultra-sensitive explosives sensor

We knew that well-trained bees were capable of sniffing out dynamite and other explosives, but researchers at MIT have now come up with a slightly less militant way to use our winged friends as bomb detectors. A team of chemical engineers at the school recently developed a new, ultra-sensitive sensor that's sharp enough to detect even one molecule of TNT. Their special ingredient? Bee venom. Turns out, a bee's poison contains protein fragments called bombolitins, that react to explosive compounds. To create the detector, researchers applied these bombolitins to naturally fluorescent carbon nanotubes. Whenever an explosive molecule binds with the protein fragments, the interaction will alter the wavelength of the carbon cylinder's fluorescent light. The shift is too small for the naked eye to pick up on, but can be detected using specially designed microscopes. If it's ever developed for commercial use, the sensor could provide a more acute alternative to the spectrometry-based detectors used at most airport security checkpoints. At the moment, however, the technology isn't quite ready to be deployed on a widespread basis, so feel free to keep on living in fear. Full PR after the break.

Amar Toor05.10.2011

Self-strengthening polymer nanocomposite works best under pressure

No one keeps carbon nanotubes down -- especially not these guys. The always popular allotropes have been enlisted by researchers at Rice University to create a composite material that gets stronger under pressure. When combined with polydimethylsiloxane, a rubbery polymer, the tubes form a nanocomposite that exhibits self-strengthening properties also exhibited in bones. During testing, the team found the material increased in stiffness by 12 percent after 3.5 million compressions. Apparently, the crew is stumped on why it reacts this way, but is no less eager to see it working in the real world -- discussion is already underway to use the stuff as artificial cartilage. And here we thought aerogel was cool. Full PR after the break.

Christopher Trout03.27.2011